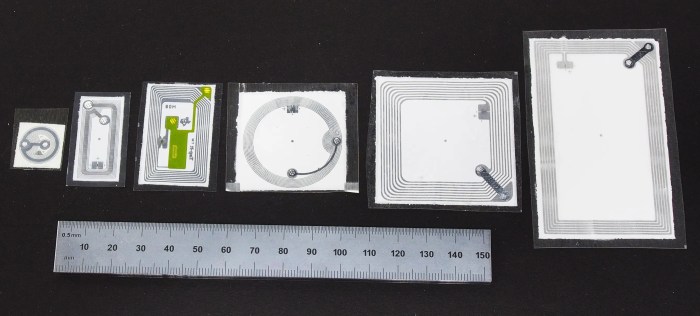

Ge develops stamp sized explosives detection rfid tags – GE develops stamp-sized explosives detection RFID tags – a game-changer in security tech! Imagine tiny, almost invisible tags capable of sniffing out explosives. This revolutionary tech uses advanced sensor technology and miniaturized RFID to detect explosive materials, transmitting data to a reader with incredible speed and accuracy. Think airport security, but way more efficient and less intrusive. This isn’t just about speeding up lines; it’s about making the world a safer place, one tiny tag at a time.

The technology behind these miniature marvels is complex, blending advanced materials science with cutting-edge electronics. From the choice of materials to the manufacturing process, every aspect has been meticulously designed to ensure both sensitivity and reliability. The power source, operational lifetime, and data security are all crucial considerations, and GE’s innovation addresses each with impressive solutions. We’ll delve into the nitty-gritty, exploring the technical details, applications, and the future implications of this groundbreaking development.

Materials Science and Manufacturing Considerations: Ge Develops Stamp Sized Explosives Detection Rfid Tags

Miniaturizing explosive detection technology to the size of a postage stamp presents a formidable challenge, demanding innovative solutions in materials science and manufacturing. Creating such a sensitive, reliable device at this scale requires careful consideration of material properties and precise manufacturing techniques. The constraints imposed by size and the need for high sensitivity necessitate a delicate balance between functionality, durability, and cost-effectiveness.

Material Selection for RFID Explosive Detection Tags

The choice of materials for both the casing and internal components of the RFID tag is critical to its performance and longevity. The casing must be robust enough to withstand environmental factors like temperature fluctuations, humidity, and potential physical impacts. Simultaneously, it needs to be thin and lightweight to maintain the overall miniature size. Internal components, including the antenna, sensor, and microchip, must be selected for their sensitivity, stability, and compatibility with the chosen manufacturing processes. The materials must also be non-reactive with the target explosives to prevent false positives or degradation of the sensor’s performance.

Potential Material Limitations and Their Impact on Performance

Several material limitations can significantly impact the performance of these miniature explosive detection tags. For example, the choice of a flexible casing material might compromise its structural integrity, leading to potential damage and malfunction. Similarly, the use of certain metals in the antenna design might affect its sensitivity or lead to signal interference. The selection of a microchip with low power consumption is essential to extend the tag’s operational lifespan, but this might come at the cost of reduced processing power or sensitivity. A lack of sufficient space within the miniature tag can limit the size and sensitivity of the explosive sensor itself, directly impacting detection capabilities.

Manufacturing Techniques for Miniature RFID Tags

Producing these incredibly small and complex devices requires advanced manufacturing techniques. Microfabrication techniques, such as photolithography and thin-film deposition, are likely candidates. These methods allow for the precise patterning and deposition of materials onto substrates, enabling the creation of intricate circuitry and miniature sensors. Additive manufacturing, or 3D printing, could offer advantages in creating complex three-dimensional structures and integrating multiple components, but the resolution and material choices might need further development for this application. Other techniques such as micro-molding or MEMS (Microelectromechanical Systems) fabrication are also viable options, each with its own set of advantages and disadvantages regarding precision, cost, and scalability.

| Material | Flexibility | Durability | Cost |

|---|---|---|---|

| Polyimide | High | Moderate | Moderate |

| Silicon | Low | High | High |

| Kapton | High | High | Moderate |

| PET | High | Low | Low |

GE’s stamp-sized explosives detection RFID tags represent a significant leap forward in security technology. The potential applications are vast, ranging from enhanced airport security to revolutionizing mail sorting and package screening. While challenges remain, particularly in addressing data security and minimizing false positives, the potential benefits are undeniable. This technology promises a future where explosive threats are detected swiftly and efficiently, making our world a safer place. The miniaturization and efficiency are impressive, paving the way for wider deployment and even more innovative applications down the line. It’s a small tag with a big impact.

Insurfin Berita Teknologi Terbaru

Insurfin Berita Teknologi Terbaru